Lattice or mesh-like structures can be successfully 3D printed using a conventional [FDM] 3D printer with micro-level strings to a degree that is not possible using standard 3D slicing protocols. GCODE can be defined directly; however, the extremely complex nature of defining geometry whilst simultaneously controlling these parameters makes it a tedious task. A program written by Andy Gleadall, called FullControl, packages a direct way of controlling GCODE in a usable interface. This is how such lattices and meshes were made.

Example Mesh Designs

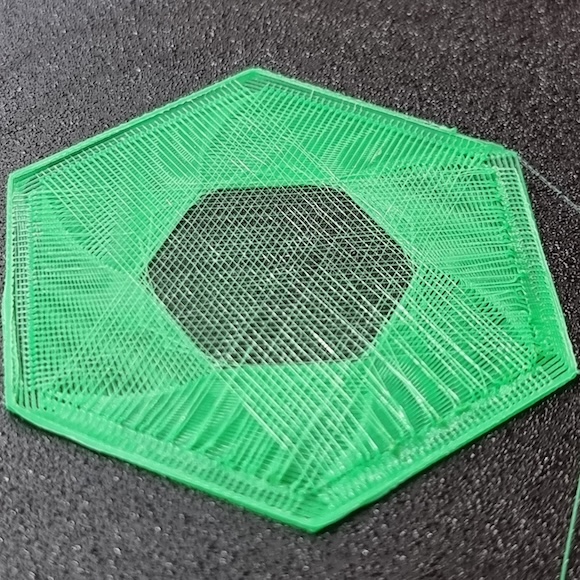

A TPU dodecagonal mesh; 960 strings

A mesh made from FibreFlex durable material.

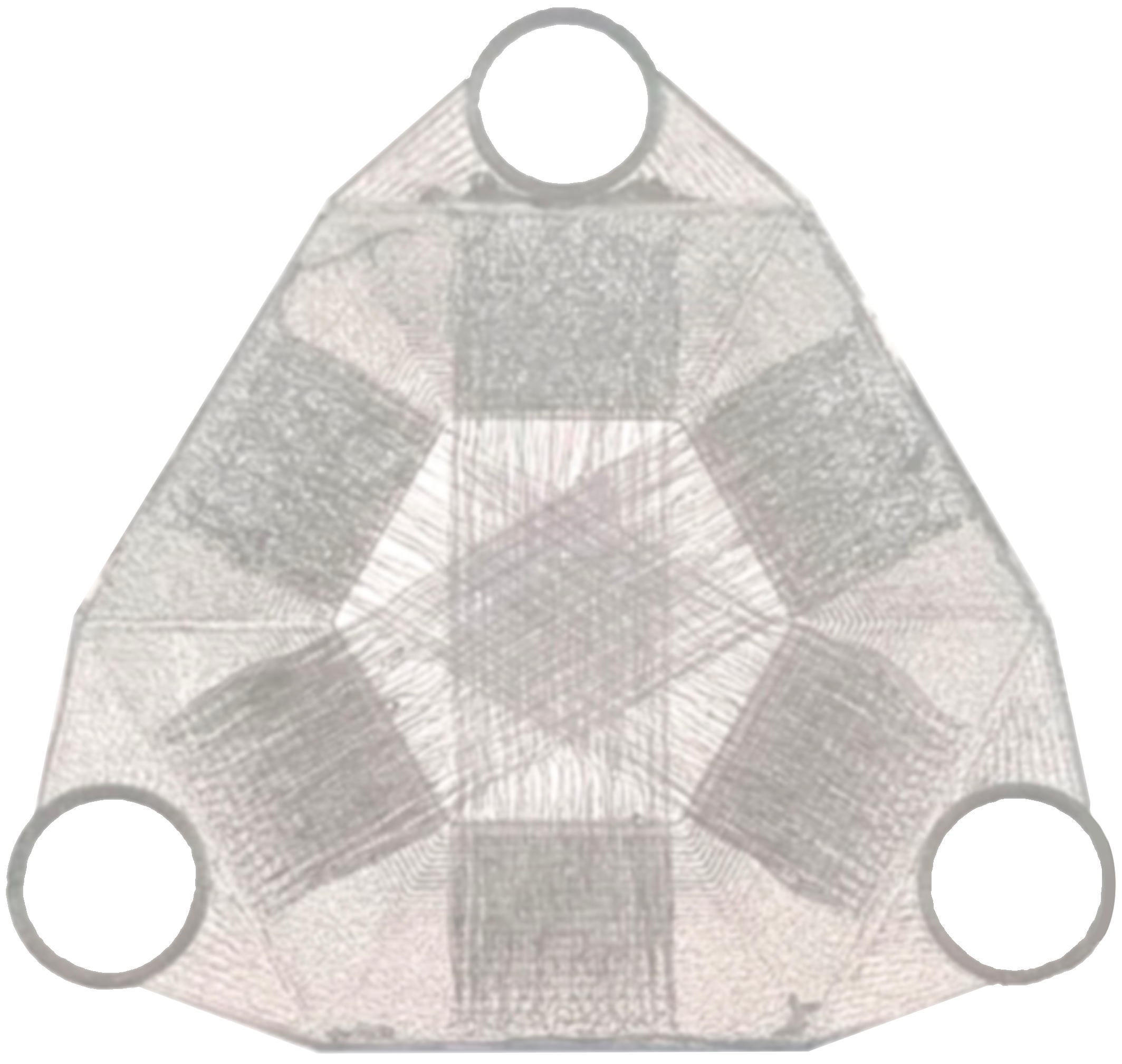

Layers of stacked TPU meshes acting as a liquid filter; 2700 strings in total

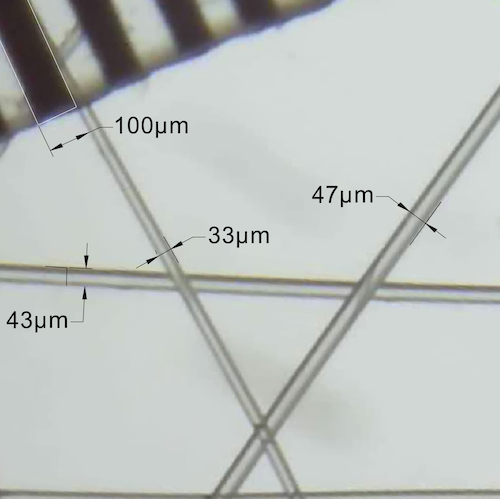

An application to penetrate cellular membranes

In existing biological research, fine grid meshes comprised of nylon strings with diameters of less then 50µm are used to interact with cells by attaching a cluster of cells to the mesh and uniformly pulling it apart. If the mesh strings and the cellular sizes are similar, it is possible for the cell membranes to be broken allowing drugs/chemicals to be administered into the cells before the membranes chemically re-form. A mesh was formed to fit this purpose.